Choosing the best jib crane for a job should never be left to guesswork. Your jib crane will quickly become a critical part of your operation. A part of your business you cannot afford to have shutdown for frequent repairs or due to malfunctions.

Let us start with the discussion of malfunctions. A jib crane will be used in your business to move heavy loads(mover cargas pesadas) often near employees. If your jib crane breaks at an inopportune time the load could fall on an employee causing serious injury. It is important to make sure your choice of crane is sized properly for the maximum loads you intend to move. Never try to move loads that are heavier than the specifications believing there is some leeway in the numbers.

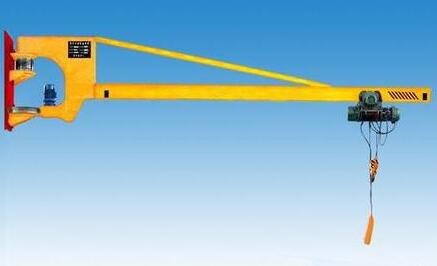

Your jib crane cables, motors, and pulleys need to be inspected on a regular basis to make sure your crane remains safe.

Choosing a jib crane from a quality manufacturer is important. You need a crane that can run full-time when your business is running, even if that is 24 hours per day, seven days per week. You can plan for routine maintenance of your crane, but unexpected repairs cost you productivity, lost wages, and can lead to late deliveries.

You should make sure the company your buy your crane from provides fast service and has parts available quickly. Downtime on a crane for a day or two can usually be overcome with forklifts, or shuffling work to another area, but extended downtime is expensive and painful.

Does the company provide on-site service, or does your maintenance team need to be trained to install parts? Make sure you ask companies how they provide service. This simple question may change your mind on whether saving $1000 on a cheaper crane makes sense or not.

Should you consider buying a used jib crane? If you are on a tight budget, that is always an option. It is critical to have the crane carefully inspected to see if all parts are in-place and in good working order. Also, check with the manufacturer, or local dealer, to make sure they still service that model and to make sure parts are easy to get. Used cranes may need repairs sooner than a new crane(grua nueva).

Another important consideration is your installation location. Make sure you have proper footing and supports for the crane. A jib crane’s design puts a lot of stress on mounts. Make sure your maintenance team adds inspecting all mounting points to their routine maintenance logs.

A last point we would like to make about jib cranes is training. Picking the best jib crane is just the start of your work. After it is installed you need to make sure your employees are properly trained. Simple mistakes can lead to broken equipment, lost inventory, and injuries.

A jib crane will increase your productivity and make work much easier for employees. Just make sure you do the proper research to choose a jib crane that handles all your jobs, provides reliable service, and your employees are properly trained.