Choosing the appropriate crushers for aggregate production is crucial for optimizing efficiency and achieving desired results in construction projects. With various types of crushers available, each offering unique advantages, selecting the right equipment is essential for maximizing productivity and minimizing operational costs.

Understanding the Importance

Crushers play a pivotal role in the production of aggregates, which are essential for constructing roads, buildings, and other infrastructure projects. Selecting the right crushers for aggregates can significantly impact the quality and cost-effectiveness of the aggregate production process.

Types of Crushers

There are several types of crushers commonly used in aggregate production:

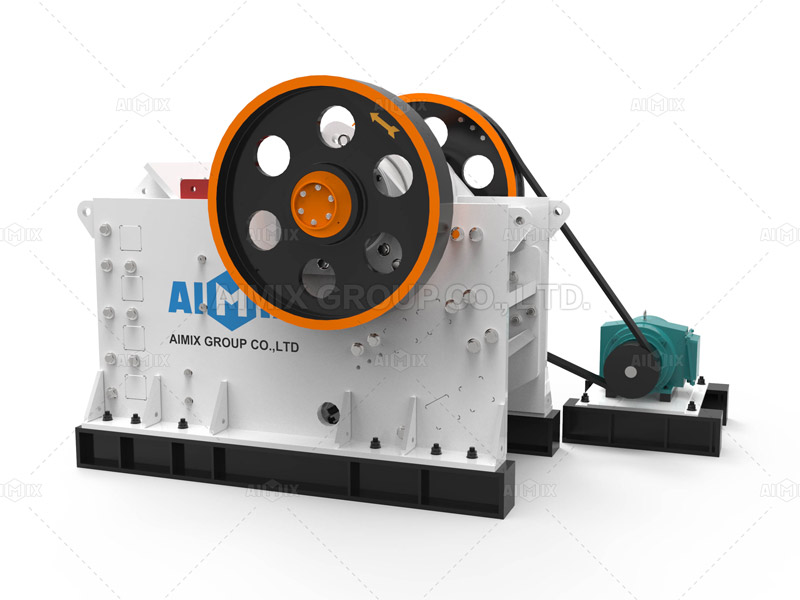

- Jaw Crushers: Ideal for primary crushing, jaw crusher machines are known for their reliability and high capacity.

- Impact Crushers: These crushers excel at producing cubical-shaped aggregates and are suitable for both primary and secondary crushing.

- Cone Crushers: Well-suited for secondary and tertiary crushing, cone crushers offer versatility and excellent particle shape control.

- VSI Crushers: Vertical Shaft Impact (VSI) crushers are ideal for shaping and producing high-quality aggregates.

Comparing Crusher Types

When choosing among jaw crushers, impact crushers, cone crushers, and VSI crushers, consider the following:

- Application: Determine the primary application of the crusher (e.g., primary crushing, secondary crushing, shaping) to narrow down options.

- Particle Size: Consider the desired particle size of the final product and choose a crusher for sale that can achieve the required size reduction.

- Capacity: Evaluate the production capacity of each crusher type to ensure it meets the project’s production requirements.

- Particle Shape: Assess the impact of each crusher type on the shape of the aggregates produced and select the one that meets the quality standards.

- Operating Costs: Compare the operating costs, including maintenance, energy consumption, and wear parts costs, to determine the most cost-effective option.

Getting the Best Price

To get the best price for an aggregate crusher, consider the following strategies:

- Research: Compare prices from multiple suppliers and manufacturers to ensure you’re getting competitive quotes.

- Negotiate: Don’t hesitate to negotiate with suppliers to get the best deal. Ask about discounts, bulk pricing, or package deals.

- Consider Total Cost of Ownership: Look beyond the initial stone crusher plant price and consider factors such as maintenance costs, spare parts availability, and energy efficiency.

- Explore Financing Options: Investigate financing options such as equipment leasing or loans to spread out the cost over time.

- Ask About Warranties: Inquire about warranties and after-sales support to ensure you’re protected in case of any issues.

Conclusion

Choosing the right crushers for aggregates is essential for maximizing efficiency and achieving quality outcomes in construction projects. By understanding the various types of crushers, comparing their features, considering factors such as application, particle size, capacity, operating costs, and implementing strategies to get the best price, construction professionals can select equipment that meets their production needs while minimizing costs and environmental impact.