Block making machines serve to produce construction building blocks for both commercial and residential structures. With the increasing availability in the number of models, making a decision can be an overwhelming process. A poor choice can lead to selecting a machine that will present problems hence poor productivity. Therefore consideration of the below tips will guide you to ensure you choose an efficient design. Furthermore, you should spare time to do in-depth research for comparison purposes so that you can go for the best supplier.

Storage Space.

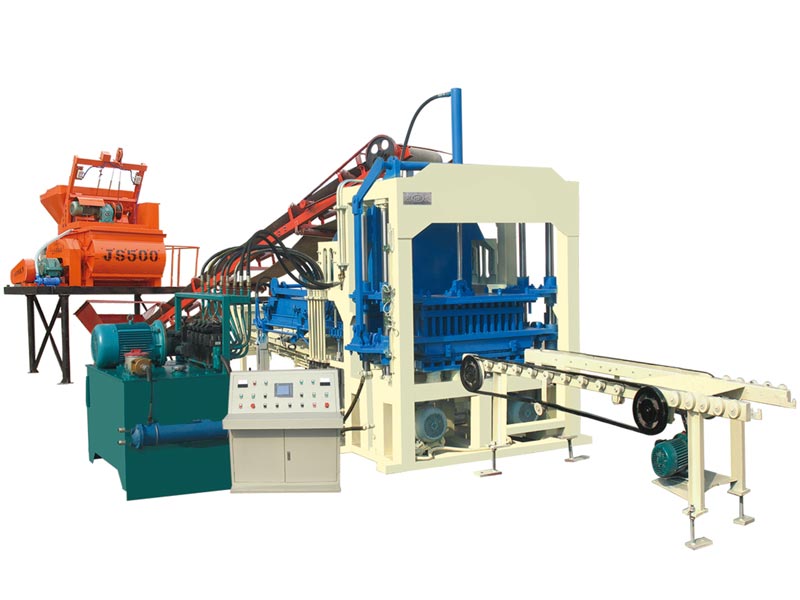

Before deciding on the size of the block making machine in Cambodia, you should consider the available amount of storage space you have. The devices come in a variety of sizes, depending on their functionality levels. They have different characteristics that determine their level of output, which also influences their sizing. Also, the available facilities that you have to help it perform will matter. If you have minimal space, you will have to choose a smaller size so that it can fit and leave enough room for the movement of people when collecting the blocks for storage. Getting a more massive type when you do not have enough space will inconvenience you in terms of looking for extra spaces to accommodate production materials.

Needs.

There are many reasons why you might require a block making machine. Outlining all your objectives can guide you in choosing a model that will suit all your needs and preferences. If you have a high demand for such blocks, it will call for the purchasing of a machine that can produce without delays. Selecting a smaller capacity block machine will lead to time wastage while your energy bills increase. However, if you are just getting into the industry, a modest-sized tool will work just fine to meet your demands. The machines have different production capacities despite their sizes; hence you need to be keen when purchasing. Furthermore, the molds for making blocks come in a variety of models, and thus you have to ensure the machine can accommodate them for effective production.

Price.

Just like any other item, what you spend is what you get. The pricing of block making machines varies widely depending on the supplier, design, and size. While you will come across some that are affordable, other models can be quite costly. When selecting, it is advisable to check on the aspects that determine the pricing factor so that you can invest without second thoughts. You can opt for a cheaper brick machine price in Cambodia, but in the long run, you end up incurring extra costs in repairs and maintenance. Furthermore, it can have a slow production capacity, which is a bad reputation for your business. On the other hand, other designs will have you spend more money, but they meet all your available demands within a shorter time hence lower energy costs.

Choosing a block making machine requires some time to consider the tips mentioned above for you to make a decision that will not disappoint. While checking on the pricing factor, you can have a budget to guide you further so that you don’t end up spending more than you have.