In the dynamic realm of construction, the pace of progress is often dictated by the availability of fundamental materials, with concrete standing as the most crucial. The methodology for producing this essential building block has evolved significantly, and dry mix plants represent a paradigm shift towards unparalleled efficiency. Unlike traditional wet mix plants that combine all ingredients with water before dispatch, dry mix concrete batch plant transports the precise blend of cement, sand, and aggregate to the site in a dry state, with water added only at the point of discharge. This fundamental distinction in process unlocks remarkable gains in production velocity.

However, quantifying the speed of a dry mix plant is not a matter of a single metric; it is an intricate interplay of mechanical cycle times, logistical orchestration, and the unique demands of the project at hand. Understanding this multifaceted tempo is key to appreciating how this technology accelerates project timelines from the foundation up.

The Production Cycle: A Symphony of Precision and Pace

The raw speed at which a dry mix plant can operate is a function of its automated batching cycles and the seamless flow of materials from storage to transit.

The Batching and Loading Sequence

The heart of the plant’s speed lies in its batching system. Modern dry mix plants are equipped with highly accurate, computer-controlled weigh batchers that simultaneously draw from compartments holding cement, sand, and aggregates. This concurrent weighing process, as opposed to a sequential one, drastically compresses the cycle time. A single cycle—encompassing the gate opening, material weighing, and discharge into the waiting mixer truck—can be completed in a matter of minutes. For a high-capacity ready mix plant for sale, this means a new truck can be loaded with several cubic meters of dry material every three to five minutes. This rapid-fire loading capability allows a well-organized plant to service a continuous convoy of trucks, maintaining an unbroken supply chain to the construction site.

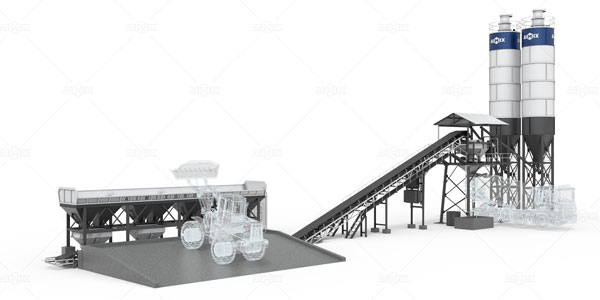

Maximizing Output Through Silo and Conveyor Design

The sustained speed of production is heavily dependent on the plant’s supporting infrastructure. The capacity of the cement silos and aggregate storage bins is a critical determinant. Large-volume silos reduce the frequency of cement deliveries, which can otherwise create a bottleneck. Similarly, efficient conveyor systems that swiftly move aggregates from ground storage to the elevated batcher ensure the plant is never waiting for raw materials. The synergy between ample material reserves and high-speed conveyance systems is what enables a dry mix plant to maintain its peak production tempo for hours on end, feeding large-scale pours without interruption.

The On-Site Finale: From Dry Mix to Wet Concrete

While the plant’s output is measured in dry batches, the ultimate goal is the placement of wet concrete. The final phase of activation is just as critical to the overall timeline.

The Transit and Mixing Phase

The clock continues to tick during transit. Inside the rotating drum of the mixer truck, the dry ingredients begin a preliminary blending. Upon arrival at the site, the driver connects a water tank to the truck’s system. The introduction of water and the subsequent mixing cycle within the drum is a precisely timed operation. This final mixing typically takes several minutes to achieve a perfectly homogeneous consistency. The total elapsed time from the plant’s loading bay to a ready-to-pour product on-site is a composite of travel duration and this essential final mix cycle. For projects in close proximity to the concrete batch plant for sale, concrete can be ready for placement in a remarkably short timeframe.

Advantages in Cold Weather and Logistics

The dry mix process confers a distinct advantage in its resistance to environmental challenges. In cold climates, the risk of freezing is virtually eliminated because water is not added until the last possible moment. This extends the viable construction season. Furthermore, since the concrete is not “aging” in the drum during transit, trucks have a longer window to reach the site without compromising the quality of the final product. This logistical flexibility prevents waste and ensures that the speed of production at the plant translates effectively into speed of placement at the project.

Beyond Raw Speed: The Strategic Implications of Rapid Production

The velocity of a dry mix plant transcends mere quickness; it reshapes project planning and execution, offering strategic depth that goes beyond the clock.

Enabling Just-in-Time Delivery

This high-velocity production model is the engine for a just-in-time delivery system. Project managers can coordinate concrete supply with surgical precision, scheduling truck arrivals to match the exact pace of the placement crew. This minimizes on-site congestion and eliminates the need for large, temporary staging areas for pre-mixed concrete. It also drastically reduces the risk of concrete setting in the truck due to delays, a common and costly issue with wet mix production. The ability to produce and deliver on demand makes the construction process leaner and more responsive.

A Catalyst for Project Timelines

Ultimately, the cumulative effect of this speed is a significant acceleration of the overall project timeline. When foundations, slabs, and structural elements can be poured in rapid, continuous sequences, subsequent trades can begin their work sooner. This creates a positive ripple effect throughout the entire construction schedule. The dry mix stationary batching plant, therefore, is not just a fast machine; it is a critical tempo-setter for the entire project symphony, ensuring that the rhythm of progress never falters.