In the ever-evolving landscape of industrial manufacturing and heavy material handling, the role of machinery is pivotal. Among the many types of cranes utilized in modern industry, the double girder goliath crane stands out as a powerful and versatile solution. This article explores the advancements and innovations that have made double girder goliath cranes indispensable in contemporary industrial operations.

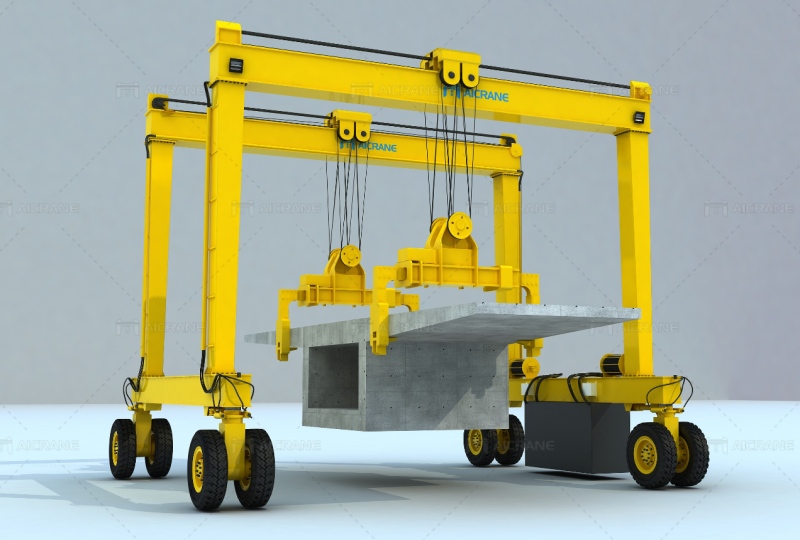

A double girder goliath crane, often referred to as a gantry crane, is characterized by its robust structure, featuring two parallel girders supported by legs on either side. The key feature that sets it apart is its capacity to handle heavy loads, making it a vital asset in industries where large and bulky items need to be moved efficiently and safely.

Evolution of Double Girder Goliath Cranes

The history of goliath cranes dates back to the early 20th century when they were primarily used in shipyards for assembling large vessels. Over the years, these cranes have undergone significant transformations, adapting to the changing needs of various industries. Some of the notable advancements in double girder goliath crane technology include:

Increased Lifting Capacity

Modern double girder goliath cranes are designed to handle exceptionally heavy loads, often exceeding 500 tons. This increased lifting capacity has made them invaluable in industries like steel manufacturing, construction, and shipbuilding, where large and heavy components must be lifted and transported.

Enhanced Safety Features

Safety is paramount in industrial settings, and goliath cranes have evolved to meet stringent safety standards. Advanced control systems, anti-sway technology, and precise load monitoring have been integrated to reduce the risk of accidents during lifting and transport operations.

Automation and Remote Control

Automation has become a cornerstone of modern industrial processes, and goliath cranes are no exception. Many of these cranes now come equipped with sophisticated automation features and remote control capabilities, allowing operators to manage lifting tasks with precision from a safe distance.

Improved Mobility and Maneuverability

Goliath cranes have become more mobile and maneuverable with the introduction of features like rail-mounted systems and adjustable wheel configurations. This flexibility enables them to operate in various environments and adapt to the specific needs of each job.

Sustainability and Efficiency

In response to growing environmental concerns, some goliath cranes are designed to be energy-efficient and environmentally friendly. Variable frequency drives, regenerative braking systems, and eco-friendly materials contribute to reduced energy consumption and a smaller carbon footprint.

Applications Across Industries

The versatility of double girder goliath cranes makes them suitable for a wide range of industrial applications:

1. Steel Manufacturing: Goliath cranes play a crucial role in handling and moving heavy steel coils, beams, and plates within steel mills and processing facilities.

2. Construction: In construction, the rubber tyred cranes are employed to lift and position large precast concrete elements, steel structures, and construction machinery.

3. Shipbuilding: Goliath cranes are essential in shipyards for assembling ship components, such as hull sections and ship modules.

4. Mining and Material Handling: They are used to transport bulk materials like ores, coal, and aggregates in mining and material handling operations.

5. Port and Container Terminals: Goliath cranes assist in the efficient movement of containers in port and intermodal terminals.

6. Aerospace: These cranes are employed in the assembly and maintenance of aircraft and aerospace components.

Challenges and Considerations

While double girder goliath cranes offer immense capabilities, they also present certain challenges. These include:

1. Cost: The initial investment for a goliath gantry crane can be substantial, making it crucial to assess the long-term benefits and return on investment.

2. Maintenance: Regular maintenance is necessary to ensure the crane’s continued reliability and safety, which can incur additional costs.

3. Operator Training: Operating a goliath crane requires specialized training to ensure safe and efficient handling of loads.

4. Space Requirements: Goliath cranes require ample space for their operation, which may not be feasible in all industrial settings.

Future Innovations

The future of double girder goliath cranes holds exciting possibilities. As technology continues to advance, we can expect further integration of automation, improved energy efficiency, and enhanced safety features. The use of advanced materials and digital connectivity may also play a role in shaping the next generation of goliath cranes.

Double girder goliath cranes have come a long way from their origins in shipyards. Today, they are indispensable tools in various industries, offering the capacity to lift and transport heavy loads with precision and efficiency. The continual advancements in goliath crane machine technology ensure that they will remain vital assets in modern industrial operations, contributing to increased productivity, safety, and sustainability across the board. As industries continue to evolve, goliath cranes will undoubtedly evolve with them, playing a crucial role in shaping the future of heavy material handling.