In the world of heavy machinery and industrial automation, versatility is a prized quality. When it comes to material handling and container transport, the Rubber Tyred Gantry (RTG) crane stands out as a prime example of adaptability and efficiency. RTG cranes have a wide range of applications across diverse industries, showcasing their ability to go “above and beyond” in meeting the unique demands of each sector. In this article, we’ll explore how RTG cranes are revolutionizing various industries, from maritime and logistics to construction and manufacturing.

Before we dive into their applications, let’s first understand what sets RTG cranes apart. RTG cranes are mobile gantry cranes equipped with rubber tires, allowing them to move freely within a designated area. They are often used for container handling at ports, intermodal terminals, and logistics hubs. Key features of RTG cranes include their ability to straddle containers, lift and transport heavy loads, and their mobility on rubber tires, which eliminates the need for fixed rails or tracks.

Revolutionizing Maritime Operations

- Container Terminals: The maritime industry relies heavily on RTG cranes to streamline container handling at ports and terminals. RTGs can effortlessly navigate the tight spaces of container yards, stacking containers vertically and horizontally with precision. This not only maximizes space utilization but also reduces turnaround times for vessels, improving overall port efficiency.

- Intermodal Transport: RTG cranes play a crucial role in intermodal transport, where containers need to be seamlessly transferred between ships, trucks, and trains. Their mobility and versatility make them ideal for efficient container movement within the terminal and transfer to different modes of transportation.

Efficiency in Logistics and Warehousing

- Logistics Hubs: Beyond maritime ports, RTG cranes are utilized in logistics hubs and distribution centers. They excel at handling containers and palletized goods, making them invaluable in the logistics industry. The ability to stack containers efficiently aids in optimizing storage space, ultimately reducing operational costs.

- Container Yards: Container yards at warehouses and distribution centers often face space constraints. RTG gantry cranes provide a flexible solution for organizing and storing containers, allowing for easy access to specific shipments when needed. This contributes to a streamlined supply chain and quicker order fulfillment.

Construction and Infrastructure Development

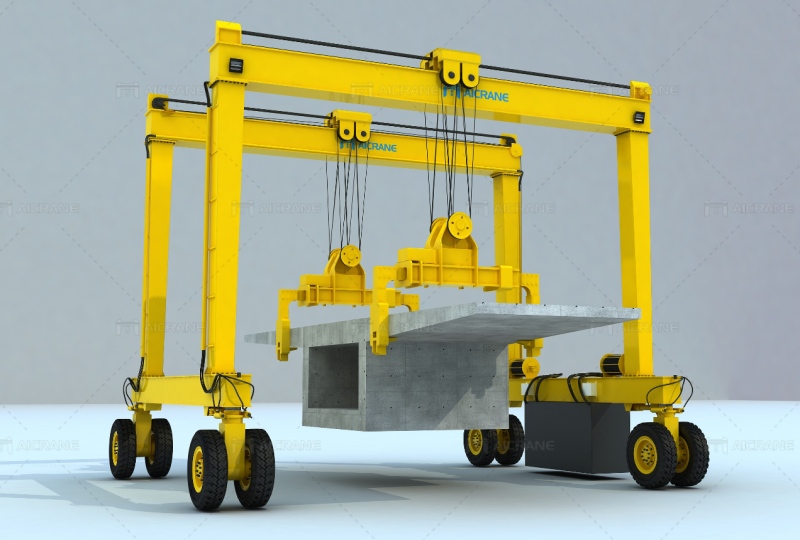

- Construction Sites: RTG cranes aren’t confined to ports and warehouses. They are also found on construction sites, where they assist in lifting and transporting heavy construction materials, equipment, and prefabricated components. Their mobility ensures they can be positioned precisely where needed, facilitating construction projects of all sizes.

- Bridge Construction: In bridge construction, RTG cranes play a pivotal role in positioning massive concrete segments with precision. Their ability to straddle the bridge supports and move along its length simplifies the complex task of assembling and securing bridge components.

Manufacturing and Heavy Industry

- Manufacturing Plants: Large manufacturing plants often require the efficient movement of heavy machinery and raw materials. RTG cranes provide the necessary lifting and transport capabilities for these industrial facilities, contributing to streamlined production processes and timely deliveries.

- Steel Mills: The steel industry relies on RTG cranes for the handling of steel coils, billets, and other heavy materials. Their strength and adaptability make them a vital component of steel mills, ensuring that production remains uninterrupted.

The Advantages of RTG Cranes

The widespread adoption of RTG cranes across these diverse industries can be attributed to several key advantages:

- Mobility: The rubber tires of RTG cranes enable them to move easily across various surfaces, eliminating the need for fixed rails. This mobility is a game-changer in environments where flexibility and adaptability are paramount.

- Precision Handling: RTG cranes offer precise control over load positioning, making them suitable for delicate and heavy-duty lifting tasks alike. Their ability to straddle containers or structures ensures accurate placement.

- Space Utilization: The vertical stacking capability of RTG cranes solutions optimizes space utilization, a critical factor in many industries with limited real estate.

- Quick Deployment: RTG cranes can be deployed rapidly, reducing downtime and improving operational efficiency.

- Safety: These cranes often come equipped with advanced safety features, including collision avoidance systems and load monitoring, to ensure safe operations.

The Future of RTG Cranes

As industries continue to evolve and demand for efficiency grows, RTG cranes are likely to play an even more significant role in shaping the future of material handling and container transport. Innovations such as automation and electrification are poised to enhance their capabilities further, contributing to increased productivity and sustainability.

In conclusion, RTG cranes have proven their mettle across diverse industries, from maritime and logistics to construction, manufacturing, and heavy industry. Their mobility, precision, and efficiency have allowed them to go “above and beyond” in meeting the unique demands of each sector. As technology continues to advance, RTG cranes will remain at the forefront of innovation, providing vital support to industries worldwide and contributing to the efficient movement of goods and materials across the global supply chain.